Product Description

Product Description

CZPT planetary gear motor

Technical data:

1. Ratio range: 8.1-191

2. Input power: 0.12-270 KW

3. Permit torque rang: ≤ 50000 N. M

4. Output speed: 0.3~205 r/min

5. Structure: Foot-mounted, flange-mounted, shaft-mounted

| Input structure | motor,IEC flange |

| Output speed | motor,IEC flange,input shaft |

| solid shaft, hollow shaft with key,with shrink disk |

Characteristic:

1. Adopt optimized design, module combination, right angle output, space reduction

2. High strength and longevity gears

3. Can be combined with various motors, wider ratio range

4. Big output torque, smoothly startup, high efficiency

Production pictures:

———————————————————————————————————————————————

FAQ:

1.Are you a factory or trader ?

We are a professional factory which has 20 years history specialized in gear transmission .

2.MOQ:

Our MOQ is 1pcs. However there is 1 handling cost $150 for the single order which less than $3000.00

3. Warranty

Our warranty is 12months

4. Payment term

100% T/T in advance and LC at sight .

5. Do you accept customization ?

YES.SGR have strong R&D team, we can provide customizable service according to requirements.

6. Packing

Generally we use standard export plywood case to arrange the shipment .

7. Delivery time

In normal ,time of delivery is 30days after receiving the prepayment .

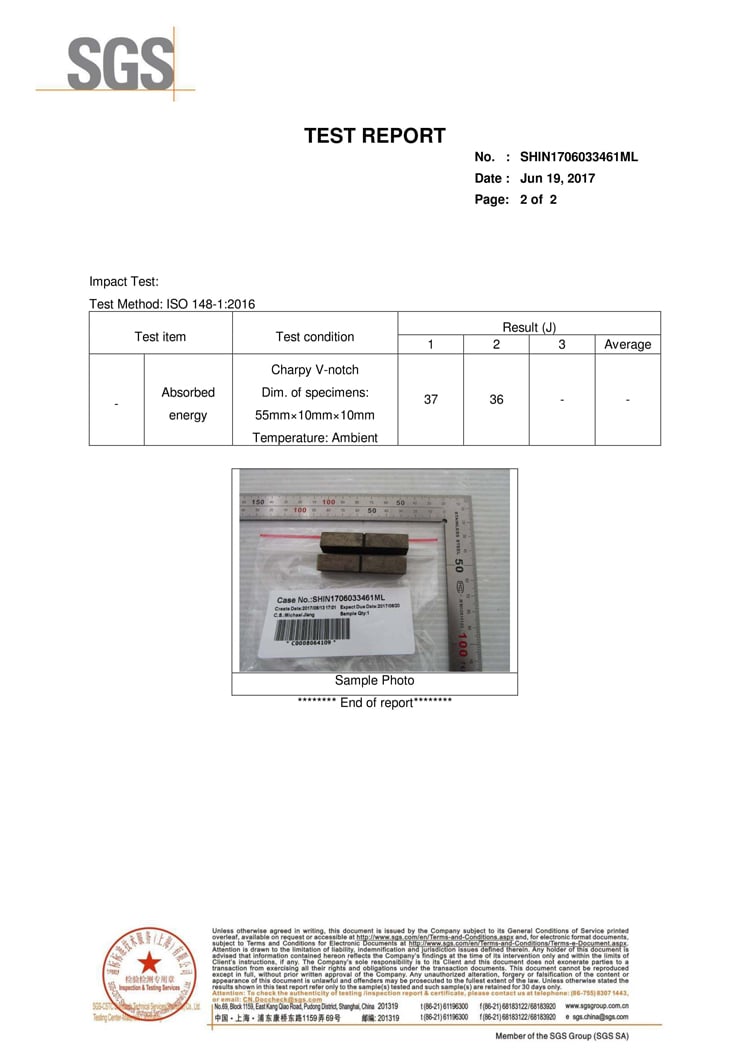

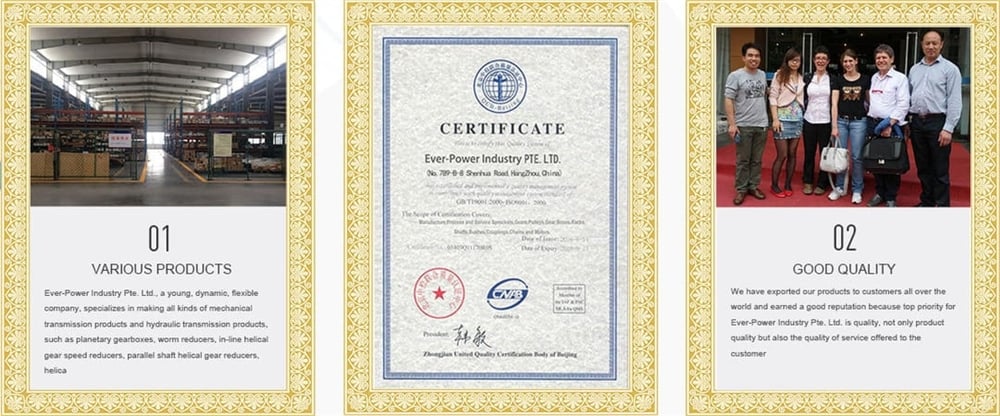

8. What kinds of certification do you use ?

DNV-ISO9001:2008, SGS,CE etc, And new products patent.

9. What kinds of inspection you do before shipment ?

We do temperature test, noise, and oil leak inspection and commissioning before shipment.

10.How do you solve if the production have problem ?

Mostly, we don’t need customer send the goods back to us. Because the cost is very high, if there meets a problem,we firstly ask for the pictures for damaged parts. And base on the pictures, we can have a basic idea for the defect reason. Our guarantee is 12 months, if during the guarantee, we can supply repair .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types, Applications, and Lubrication of Planetary Gearboxes

A Planetary Gearbox is a device that can be used in a variety of applications. Their reduction ratios depend on the number of teeth in each gear. In this article, we will discuss the types, applications, and lubrication of planetary gearboxes. Hopefully, this article will be of help to you. If not, you can check out this article and discover more about this fascinating machine. There are many different types of planetary gearboxes.

Applications of planetary gearboxes

The planetary gearbox is a popular option for applications requiring precise positioning. Applications of the planetary gearbox range from plastic machinery to agricultural equipment, from goods & personnel lifts to industrial robotics. Some of the industries that benefit from this type of gearbox include robotics, intra-logistics, robotics for industrial automation, and medical equipment. Increasing automation is also fueling the growth of the industrial planetary gearbox market in APAC.

The compact design of planetary gears makes them excellent for reducing load inertia and maximizing torque. However, some applications require additional lubrication for sustained performance or high speeds. CZPT uses CZPT in its planetary gearboxes. In addition, lubrication prevents gear wear and minimizes noise and vibration. The planetary gearbox is also easy to install, thanks to its low-mass-inertia design.

Another application of the planetary gearbox is in axles and transfer cases. The planetary gear architecture consists of a sun gear, also called the central gear, and a ring-gear with internal teeth that are concentric to the sun gear. The two gears are connected via a carrier, and the output shaft is positioned on the ring-gear carrier. The gearbox can be configured in a variety of ways, depending on the speed-ratio requirements.

The planetary gear train is similar to that of a solar system. It comprises a sun gear and two or more outer gears, ring gear and carrier assembly. In this configuration, the outer gears are connected via a carrier and a ring gear. The planet gears are in constant mesh with each other, and power applied to one of these members will rotate the whole assembly. They are a very efficient choice for many applications.

Types

There are three types of planetary gearboxes, depending on their performance and efficiency. The basic model is highly efficient and transmits up to 97% of power input. Depending on the speed and torque that need to be transmitted, planetary gearboxes are used in many different applications. A planetary gearbox can reduce the speed of a roller or produce a more precise level of movement. Using a planetary gearbox for your printing press, for example, will maximize your gear transmission ratio.

This market research report analyzes the factors influencing the market for Planetary Gearboxes, as well as their sales and revenues. It also highlights industry trends and details the competitive landscape. It also provides a comprehensive analysis of the Planetary Gearbox industry and its drivers and restraints. It provides detailed information on the market size and future growth prospects. The study also includes an extensive discussion of the competitive landscape, identifying the top companies and key market players.

A planetary gearbox is often used to manufacture complicated machines. These gears are usually made of high-quality steel, which makes them extremely durable. Planetary gearboxes can also be used in the production of heavy machine elements. There are many benefits of a planetary gearbox, including its compactness and low mass inertia. The main advantage of a planetary gearbox is its ability to distribute torque. Compared to a normal gearbox, planetary gearboxes can provide torque that is nearly three times higher than its conventional counterpart.

The three main types of planetary gears are the single-stage, compound, and multi-stage. The general concept of a planetary gear is referred to as a compound planetary gear. This means that planetary gears are made up of one of these three basic structures: a meshed-planet structure, a shaft, and a multi-stage structure. This type of gear has multiple stages and is particularly useful for fast-dynamic laser cutting machines.

Design

A planetary gearbox is similar to a car’s transmission. All of its gears must have a certain number of teeth and be spaced equally apart. The teeth of a planet must mesh with the gears of the ring and sun to be functional. The number of teeth needed will depend on the number of planets and their spacing. This equation is a good starting point for designing a gearbox.

The dynamic properties of planetary gears are investigated using a parametric model. The stiffness of the mesh changes as the number of gear tooth pairs in contact varies during the gear rotation. Small disturbances in design realizations cause nonlinear dynamics, which results in noise and vibrations in the gear transmission. A mathematical system describing this process is developed using the basic principles of analytical mechanics. This mathematical model can be used to optimize any planetary gear.

This analysis assumes that the sun gear and planet gears have the same design modulus, which is a fundamental requirement of any mechanical gear. In reality, the ratio of these two gears is 24/16 versus -3/2. This means that a planetary gearbox’s output torque is 41.1 times the input torque. Considering this factor, we can make an accurate estimate of the total torque. The planetary gears are mounted face-to-face and connected to an electric motor.

A planetary gear set has to have a certain number of teeth that are odd or even. One way to overcome this issue is to double the number of teeth on the sun gear and the annulus gear. This will also solve irregularities. Another way to design a planetary gear set is to use the appropriate diametral pitch and module. There are many planetary gear sets available on the market, so it pays to understand the differences.

Lubrication

Lubrication for Planetary Gearboxes is important for the smooth functioning of the gear. Planetary gears are subjected to high levels of friction and heat, so they require regular lubrication. The gear housing is designed to dissipate heat away from the gear, but heat can still enter the gear, which can result in a poor lubrication condition. The best lubrication solution is synthetic oil, and the gear should be refilled with a minimum of 30 percent oil.

When lubricating a planetary gearbox, it is important to note that hydraulic oil is not suitable for planetary gearboxes, which cost over $1500. Hydraulic oil does not have the same viscosity and behavior with temperature fluctuations, making it less effective. The planetary gearbox may also overheat if a hose is not provided for case draining. A case drain hose is essential to prevent this from happening, because hot oil can cause overheating of the gearbox and damage to the gears.

Oil delivery conduits are positioned between each pair of planet gears. Each oil delivery conduit directs fresh oil toward the sun gear and the planet gear. The oil then disperses and exits from the gear train with considerable tangential velocity. The oil is redirected into a collection channel (56). The preferred embodiment uses herringbone gears, which pump oil axially outward into the channels.

The best way to choose the right type of lubrication is to consider its viscosity. Too high a viscosity will prevent the lubricant from flowing properly, which will cause metal-to-metal contact. The oil must also be compatible with the gearbox temperature. A suitable viscosity will increase the efficiency of the gearbox and prevent downtime. A reliable gearbox will ultimately result in higher profits and fewer costs.

Applications

This report examines the Industrial Planetary Gearbox Market and its current trends. It identifies the pre and post-COVID-19 effects of the industry. It outlines the advantages and disadvantages of the industrial planetary gearbox market. The report also explains the diverse financing resources and business models of the market. It includes the key players in the industry. Hence, it is essential to read this report carefully.

The report includes analysis and forecasts of the global market for planetary gearbox. It includes the product introductions, key business factors, regional and type segments, and end-users. It covers the sales and revenue of the market for each application field. The report also includes the regional and country-level market data. It also focuses on the market share of the key companies operating in the industry. It covers the competitive scenario in the global planetary gearbox market.

Another popular application for planetary gearboxes is in the toy industry. It is possible to design toys that look stunning with planetary gear systems. In addition to toys, clock makers also benefit from the planetary arrangement. In addition to producing a good-looking clock, this gearbox can reduce inertia and improve its efficiency. The planetary gearbox is easy to maintain, which makes it a good choice for clock applications.

In addition to traditional gear reductions, planetary gears are also used for 3D printing. Their huge gear ratio makes 3D printing easier. Furthermore, planetary gears are used to drive stepper motors, which turn much faster and produce a desired output. There are numerous industrial uses for planetary gearboxes. This article has explored a few of the most common ones. And don’t forget to explore their uses.

editor by Dream 2024-04-26

China Good quality Inline Planetary Gearbox Used for Arm Hole Mining Chain Saws gearbox adjustment

Product Description

Product Description

SGR planetary gear motor

Technical data:

1. Ratio range: 8.1-191

2. Input power: 0.12-270 KW

3. Permit torque rang: ≤ 50000 N. M

4. Output speed: 0.3~205 r/min

5. Structure: Foot-mounted, flange-mounted, shaft-mounted

| Input structure | motor,IEC flange |

| Output speed | motor,IEC flange,input shaft |

| solid shaft, hollow shaft with key,with shrink disk |

Characteristic:

1. Adopt optimized design, module combination, right angle output, space reduction

2. High strength and longevity gears

3. Can be combined with various motors, wider ratio range

4. Big output torque, smoothly startup, high efficiency

Production pictures:

———————————————————————————————————————————————

FAQ:

1.Are you a factory or trader ?

We are a professional factory which has 20 years history specialized in gear transmission .

2.MOQ:

Our MOQ is 1pcs. However there is 1 handling cost $150 for the single order which less than $3000.00

3. Warranty

Our warranty is 12months

4. Payment term

100% T/T in advance and LC at sight .

5. Do you accept customization ?

YES.SGR have strong R&D team, we can provide customizable service according to requirements.

6. Packing

Generally we use standard export plywood case to arrange the shipment .

7. Delivery time

In normal ,time of delivery is 30days after receiving the prepayment .

8. What kinds of certification do you use ?

DNV-ISO9001:2008, SGS,CE etc, And new products patent.

9. What kinds of inspection you do before shipment ?

We do temperature test, noise, and oil leak inspection and commissioning before shipment.

10.How do you solve if the production have problem ?

Mostly, we don’t need customer send the goods back to us. Because the cost is very high, if there meets a problem,we firstly ask for the pictures for damaged parts. And base on the pictures, we can have a basic idea for the defect reason. Our guarantee is 12 months, if during the guarantee, we can supply repair .

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Challenges in Achieving High Gear Ratios with Compactness in Planetary Gearboxes

Designing planetary gearboxes with high gear ratios while maintaining compactness presents several challenges:

- Space Constraints: As the gear ratio increases, the number of gear stages required also increases. This can lead to larger gearbox sizes, which may be challenging to accommodate in applications with limited space.

- Bearing Loads: Higher gear ratios often result in increased loads on the bearings and other components due to the redistribution of forces. This can impact the durability and lifespan of the gearbox.

- Efficiency: Each gear stage introduces losses due to friction and other factors. With multiple stages, the overall efficiency of the gearbox can decrease, affecting its energy efficiency.

- Complexity: Achieving high gear ratios can require complex gear arrangements and additional components, which can lead to increased manufacturing complexity and costs.

- Thermal Effects: Higher gear ratios can lead to greater heat generation due to increased friction and loads. Managing thermal effects becomes crucial to prevent overheating and component failure.

To address these challenges, gearbox designers use advanced materials, precise machining techniques, and innovative bearing arrangements to optimize the design for both compactness and performance. Computer simulations and modeling play a critical role in predicting the behavior of the gearbox under different operating conditions, helping to ensure reliability and efficiency.

Recent Advancements in Planetary Gearbox Technology

Advancements in planetary gearbox technology have led to improved performance, efficiency, and durability. Here are some notable developments:

High-Efficiency Gearing: Manufacturers are using advanced materials and precision manufacturing techniques to create gears with optimized tooth profiles. This reduces friction and enhances overall efficiency, resulting in higher power transmission with lower energy losses.

Enhanced Lubrication: Innovative lubrication systems and high-performance lubricants are being employed to ensure consistent and reliable lubrication even in extreme conditions. This helps to reduce wear and extend the lifespan of the gearbox.

Compact Designs: Engineers are focusing on designing more compact and lightweight planetary gearboxes without compromising their performance. This is particularly important for applications with limited space and weight constraints.

Integrated Sensors: Planetary gearboxes are now being equipped with sensors and monitoring systems that provide real-time data on temperature, vibration, and other operating parameters. This allows for predictive maintenance and early detection of potential issues.

Smart Gearboxes: Some modern planetary gearboxes are equipped with smart features such as remote monitoring, adaptive control, and data analysis. These features contribute to more efficient operation and better integration with automation systems.

Advanced Materials: The use of high-strength and wear-resistant materials, such as advanced alloys and composites, improves the durability and load-carrying capacity of planetary gearboxes. This is particularly beneficial for heavy-duty and high-torque applications.

Customization and Simulation: Advanced simulation and modeling tools enable engineers to design and optimize planetary gearboxes for specific applications. This customization helps achieve the desired performance and reliability levels.

Noise and Vibration Reduction: Innovations in gear design and manufacturing techniques have led to quieter and smoother-running planetary gearboxes, making them suitable for applications where noise and vibration are concerns.

Environmental Considerations: With growing environmental awareness, manufacturers are developing more eco-friendly lubricants and materials for planetary gearboxes, reducing their ecological footprint.

Overall, recent advancements in planetary gearbox technology are aimed at enhancing efficiency, durability, and versatility to meet the evolving demands of various industries and applications.

Role of Sun, Planet, and Ring Gears in Planetary Gearboxes

The arrangement of sun, planet, and ring gears is a fundamental aspect of planetary gearboxes and significantly contributes to their performance. Each gear type plays a specific role in the gearbox’s operation:

- Sun Gear: The sun gear is located at the center and is driven by the input power source. It transmits torque to the planet gears, causing them to orbit around it. The sun gear’s size and rotation speed affect the overall gear ratio of the system.

- Planet Gears: Planet gears are smaller gears that surround the sun gear. They are held in place by the planet carrier and mesh with both the sun gear and the internal teeth of the ring gear. As the sun gear rotates, the planet gears revolve around it, engaging with both the sun and ring gears simultaneously. This arrangement multiplies torque and changes the direction of rotation.

- Ring Gear (Annulus Gear): The ring gear is the outermost gear with internal teeth that mesh with the planet gears’ external teeth. It remains stationary or acts as the output shaft. The interaction between the planet gears and the ring gear causes the planet gears to rotate on their own axes as they orbit the sun gear.

The arrangement of these gears allows for various gear reduction ratios and torque multiplication effects, making planetary gearboxes versatile and efficient for a wide range of applications. The combination of multiple gear engagements and interactions distributes the load across multiple gear teeth, resulting in higher torque capacity, smoother operation, and lower stress on individual gear teeth.

Planetary gearboxes offer advantages such as compact size, high torque density, and the ability to achieve multiple gear reduction stages within a single unit. The arrangement of the sun, planet, and ring gears is essential for achieving these benefits while maintaining efficiency and reliability in various mechanical systems.

editor by CX 2023-10-08

China Custom Inline Planetary Gearbox Used for Arm Hole Mining Chain Saws manufacturer

Product Description

Product Description

SGR planetary gear motor

Technical data:

1. Ratio range: 8.1-191

2. Input power: 0.12-270 KW

3. Permit torque rang: ≤ 50000 N. M

4. Output speed: 0.3~205 r/min

5. Structure: Foot-mounted, flange-mounted, shaft-mounted

| Input structure | motor,IEC flange |

| Output speed | motor,IEC flange,input shaft |

| solid shaft, hollow shaft with key,with shrink disk |

Characteristic:

1. Adopt optimized design, module combination, right angle output, space reduction

2. High strength and longevity gears

3. Can be combined with various motors, wider ratio range

4. Big output torque, smoothly startup, high efficiency

Production pictures:

———————————————————————————————————————————————

FAQ:

1.Are you a factory or trader ?

We are a professional factory which has 20 years history specialized in gear transmission .

2.MOQ:

Our MOQ is 1pcs. However there is 1 handling cost $150 for the single order which less than $3000.00

3. Warranty

Our warranty is 12months

4. Payment term

100% T/T in advance and LC at sight .

5. Do you accept customization ?

YES.SGR have strong R&D team, we can provide customizable service according to requirements.

6. Packing

Generally we use standard export plywood case to arrange the shipment .

7. Delivery time

In normal ,time of delivery is 30days after receiving the prepayment .

8. What kinds of certification do you use ?

DNV-ISO9001:2008, SGS,CE etc, And new products patent.

9. What kinds of inspection you do before shipment ?

We do temperature test, noise, and oil leak inspection and commissioning before shipment.

10.How do you solve if the production have problem ?

Mostly, we don’t need customer send the goods back to us. Because the cost is very high, if there meets a problem,we firstly ask for the pictures for damaged parts. And base on the pictures, we can have a basic idea for the defect reason. Our guarantee is 12 months, if during the guarantee, we can supply repair .

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Smooth and Controlled Movement in Industrial Robots with Planetary Gearboxes

Planetary gearboxes play a crucial role in ensuring smooth and controlled movement in industrial robots, enhancing their precision and performance:

Reduced Backlash: Planetary gearboxes are designed to minimize backlash, which is the amount of play or free movement between gear teeth. This reduction in backlash results in precise and accurate motion control, allowing industrial robots to achieve precise positioning and repeatability.

High Gear Reduction Ratios: Planetary gearboxes offer high gear reduction ratios, allowing the robot’s motor to output higher torque while maintaining lower speed. This capability enables robots to handle heavy loads and perform tasks that require fine adjustments and delicate movements.

Compact Design: The compact and lightweight design of planetary gearboxes allows for their integration into the limited space of industrial robot joints and actuators. This compactness is crucial for maintaining the overall efficiency and agility of the robot’s movements.

Multi-Speed Capabilities: Planetary gearboxes can be designed with multiple gear stages, allowing industrial robots to operate at different speeds as needed for various tasks. This flexibility in speed selection enhances the robot’s versatility in performing tasks of varying complexities.

High Efficiency: Planetary gearboxes are known for their high efficiency, which translates to minimal energy loss during gear transmission. This efficiency ensures that the robot’s movements are smooth and consistent while optimizing energy consumption.

Torque Distribution: The arrangement of planetary gears allows for efficient distribution of torque across multiple gear stages. This feature ensures that the robot’s joints and actuators receive the appropriate amount of torque for controlled movement, even when handling varying loads.

Seamless Integration: Planetary gearboxes are designed to be easily integrated with servo motors and other robotic components. This seamless integration ensures that the gearbox’s performance is harmoniously aligned with the overall robotic system.

Precision and Accuracy: By providing precise gear reduction and motion control, planetary gearboxes enable industrial robots to perform tasks that demand high levels of precision and accuracy, such as assembly, welding, painting, and intricate material handling.

Reduced Vibrations: The reduced backlash and smooth gear engagement in planetary gearboxes contribute to minimized vibrations during robot operation. This results in quieter and more stable robot movements, further enhancing their performance and user experience.

Dynamic Load Handling: Planetary gearboxes can handle dynamic loads that may change during robot operation. Their ability to manage varying loads while maintaining controlled movement is essential for safe and reliable robot performance.

In summary, planetary gearboxes ensure smooth and controlled movement in industrial robots by minimizing backlash, offering high gear reduction ratios, providing a compact design, enabling multi-speed capabilities, maintaining high efficiency, distributing torque effectively, seamlessly integrating with robotic systems, enhancing precision and accuracy, reducing vibrations, and enabling dynamic load handling. These features collectively contribute to the precise and optimized motion of industrial robots in various applications and industries.

Impact of Temperature Variations and Environmental Conditions on Planetary Gearbox Performance

The performance of planetary gearboxes can be significantly influenced by temperature variations and environmental conditions. Here’s how these factors impact their operation:

Temperature Variations: Extreme temperature fluctuations can affect the lubrication properties of the gearbox. Cold temperatures can cause the lubricant to thicken, leading to increased friction and reduced efficiency. On the other hand, high temperatures can cause the lubricant to thin out, potentially leading to insufficient lubrication and accelerated wear.

Environmental Contaminants: Planetary gearboxes used in outdoor or industrial environments can be exposed to contaminants such as dust, dirt, moisture, and chemicals. These contaminants can infiltrate the gearbox and degrade the quality of the lubricant. Additionally, abrasive particles can cause wear on gear surfaces, leading to decreased performance and potential damage.

Corrosion: Exposure to moisture, especially in humid or corrosive environments, can lead to corrosion of gearbox components. Corrosion weakens the structural integrity of gears and other components, which can ultimately result in premature failure.

Thermal Expansion: Temperature changes can cause materials to expand and contract. In gearboxes, this can lead to misalignment of gears and improper meshing, causing noise, vibration, and reduced efficiency. Proper consideration of thermal expansion is crucial in gearbox design.

Sealing and Ventilation: To mitigate the impact of temperature and environmental factors, planetary gearboxes need effective sealing to prevent contaminants from entering and to retain the lubricant. Proper ventilation is also essential to prevent pressure build-up inside the gearbox due to temperature changes.

Cooling Systems: In applications where temperature control is critical, cooling systems such as fans or heat exchangers can be incorporated to maintain optimal operating temperatures. This helps prevent overheating and ensures consistent gearbox performance.

Overall, temperature variations and environmental conditions can have a profound impact on the performance and lifespan of planetary gearboxes. Manufacturers and operators need to consider these factors during design, installation, and maintenance to ensure reliable and efficient operation.

Advantages of Planetary Gearboxes Compared to Other Gearbox Configurations

Planetary gearboxes, also known as epicyclic gearboxes, offer several advantages compared to other gearbox configurations. These advantages make them well-suited for a wide range of applications. Here’s a closer look at why planetary gearboxes are favored:

- Compact Size: Planetary gearboxes are known for their compact and space-efficient design. The arrangement of multiple gears within a single housing allows for high gear reduction ratios without significantly increasing the size of the gearbox.

- High Torque Density: Due to their compact design, planetary gearboxes offer high torque density, meaning they can transmit a significant amount of torque relative to their size. This makes them ideal for applications where space is limited, but high torque is required.

- Efficiency: Planetary gearboxes can achieve high efficiency levels, especially when properly lubricated and well-designed. The arrangement of multiple meshing gears allows for load distribution, reducing individual gear tooth stresses and minimizing losses due to friction.

- Multiple Gear Stages: Planetary gearboxes can be designed with multiple stages, allowing for higher gear reduction ratios. This is particularly advantageous when precise control of output speed and torque is required.

- High Gear Ratios: Planetary gearboxes can achieve high gear reduction ratios in a single stage, eliminating the need for multiple external gears. This simplifies the overall design and reduces the number of components.

- Load Sharing: The multiple gear meshing arrangements in planetary gearboxes distribute loads evenly across multiple gears, reducing the stress on individual components and enhancing overall durability.

- High Precision: Planetary gearboxes offer high precision and accuracy in gear meshing, making them suitable for applications that demand precise motion control.

- Quiet Operation: The design of planetary gearboxes often leads to smoother and quieter operation compared to some other gearbox configurations, contributing to improved user experience.

Overall, the advantages of planetary gearboxes in terms of size, torque density, efficiency, versatility, and precision make them an attractive choice for a wide range of applications across industries, including robotics, automotive, aerospace, and industrial machinery.

editor by CX 2023-10-07

China OEM Inline Planetary Gearbox Used for Arm Hole Mining Chain Saws comer gearbox

Product Description

Product Description

SGR planetary gear motor

Technical data:

1. Ratio range: 8.1-191

2. Input power: 0.12-270 KW

3. Permit torque rang: ≤ 50000 N. M

4. Output speed: 0.3~205 r/min

5. Structure: Foot-mounted, flange-mounted, shaft-mounted

| Input structure | motor,IEC flange |

| Output speed | motor,IEC flange,input shaft |

| solid shaft, hollow shaft with key,with shrink disk |

Characteristic:

1. Adopt optimized design, module combination, right angle output, space reduction

2. High strength and longevity gears

3. Can be combined with various motors, wider ratio range

4. Big output torque, smoothly startup, high efficiency

Production pictures:

———————————————————————————————————————————————

FAQ:

1.Are you a factory or trader ?

We are a professional factory which has 20 years history specialized in gear transmission .

2.MOQ:

Our MOQ is 1pcs. However there is 1 handling cost $150 for the single order which less than $3000.00

3. Warranty

Our warranty is 12months

4. Payment term

100% T/T in advance and LC at sight .

5. Do you accept customization ?

YES.SGR have strong R&D team, we can provide customizable service according to requirements.

6. Packing

Generally we use standard export plywood case to arrange the shipment .

7. Delivery time

In normal ,time of delivery is 30days after receiving the prepayment .

8. What kinds of certification do you use ?

DNV-ISO9001:2008, SGS,CE etc, And new products patent.

9. What kinds of inspection you do before shipment ?

We do temperature test, noise, and oil leak inspection and commissioning before shipment.

10.How do you solve if the production have problem ?

Mostly, we don’t need customer send the goods back to us. Because the cost is very high, if there meets a problem,we firstly ask for the pictures for damaged parts. And base on the pictures, we can have a basic idea for the defect reason. Our guarantee is 12 months, if during the guarantee, we can supply repair .

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Challenges in Achieving High Gear Ratios with Compactness in Planetary Gearboxes

Designing planetary gearboxes with high gear ratios while maintaining a compact form factor poses several challenges due to the intricate arrangement of gears and the need to balance various factors:

Space Constraints: Increasing the gear ratio typically requires adding more planetary stages, resulting in additional gears and components. However, limited available space can make it challenging to fit these additional components without compromising the compactness of the gearbox.

Efficiency: As the number of planetary stages increases to achieve higher gear ratios, there can be a trade-off in terms of efficiency. Additional gear meshings and friction losses can lead to decreased overall efficiency, impacting the gearbox’s performance.

Load Distribution: The distribution of loads across multiple stages becomes critical when designing high gear ratio planetary gearboxes. Proper load distribution ensures that each stage shares the load proportionally, preventing premature wear and ensuring reliable operation.

Bearing Arrangement: Accommodating multiple stages of planetary gears requires an effective bearing arrangement to support the rotating components. Improper bearing selection or arrangement can lead to increased friction, reduced efficiency, and potential failures.

Manufacturing Tolerances: Achieving high gear ratios demands tight manufacturing tolerances to ensure accurate gear tooth profiles and precise gear meshing. Any deviations can result in noise, vibration, and reduced performance.

Lubrication: Adequate lubrication becomes crucial in maintaining smooth operation and reducing friction as gear ratios increase. However, proper lubrication distribution across multiple stages can be challenging, impacting efficiency and longevity.

Noise and Vibration: The complexity of high gear ratio planetary gearboxes can lead to increased noise and vibration levels due to the higher number of gear meshing interactions. Managing noise and vibration becomes essential for ensuring acceptable performance and user comfort.

To address these challenges, engineers employ advanced design techniques, high-precision manufacturing processes, specialized materials, innovative bearing arrangements, and optimized lubrication strategies. Achieving the right balance between high gear ratios and compactness involves careful consideration of these factors to ensure the gearbox’s reliability, efficiency, and performance.

Impact of Temperature Variations and Environmental Conditions on Planetary Gearbox Performance

The performance of planetary gearboxes can be significantly influenced by temperature variations and environmental conditions. Here’s how these factors impact their operation:

Temperature Variations: Extreme temperature fluctuations can affect the lubrication properties of the gearbox. Cold temperatures can cause the lubricant to thicken, leading to increased friction and reduced efficiency. On the other hand, high temperatures can cause the lubricant to thin out, potentially leading to insufficient lubrication and accelerated wear.

Environmental Contaminants: Planetary gearboxes used in outdoor or industrial environments can be exposed to contaminants such as dust, dirt, moisture, and chemicals. These contaminants can infiltrate the gearbox and degrade the quality of the lubricant. Additionally, abrasive particles can cause wear on gear surfaces, leading to decreased performance and potential damage.

Corrosion: Exposure to moisture, especially in humid or corrosive environments, can lead to corrosion of gearbox components. Corrosion weakens the structural integrity of gears and other components, which can ultimately result in premature failure.

Thermal Expansion: Temperature changes can cause materials to expand and contract. In gearboxes, this can lead to misalignment of gears and improper meshing, causing noise, vibration, and reduced efficiency. Proper consideration of thermal expansion is crucial in gearbox design.

Sealing and Ventilation: To mitigate the impact of temperature and environmental factors, planetary gearboxes need effective sealing to prevent contaminants from entering and to retain the lubricant. Proper ventilation is also essential to prevent pressure build-up inside the gearbox due to temperature changes.

Cooling Systems: In applications where temperature control is critical, cooling systems such as fans or heat exchangers can be incorporated to maintain optimal operating temperatures. This helps prevent overheating and ensures consistent gearbox performance.

Overall, temperature variations and environmental conditions can have a profound impact on the performance and lifespan of planetary gearboxes. Manufacturers and operators need to consider these factors during design, installation, and maintenance to ensure reliable and efficient operation.

Design Principles and Functions of Planetary Gearboxes

Planetary gearboxes, also known as epicyclic gearboxes, are a type of gearbox that consists of one or more planet gears that revolve around a central sun gear, all contained within an outer ring gear. The design principles and functions of planetary gearboxes are based on this unique arrangement:

- Sun Gear: The sun gear is positioned at the center and is connected to the input shaft. It transmits power from the input source to the planetary gears.

- Planet Gears: Planet gears are small gears that rotate around the sun gear. They are typically mounted on a carrier, which is connected to the output shaft. The interaction between the planet gears and the sun gear creates both speed reduction and torque amplification.

- Ring Gear: The outer ring gear is stationary and surrounds the planet gears. The teeth of the planet gears mesh with the teeth of the ring gear. The ring gear serves as the housing for the planet gears and provides a fixed outer reference point.

- Function: Planetary gearboxes offer various gear reduction ratios by altering the arrangement of the input, output, and planet gears. Depending on the configuration, the sun gear, planet gears, or ring gear can serve as the input, output, or stationary element. This flexibility allows planetary gearboxes to achieve different torque and speed combinations.

- Gear Reduction: In a planetary gearbox, the planet gears rotate while also revolving around the sun gear. This double motion creates multiple gear meshing points, distributing the load and enhancing torque transmission. The output shaft, connected to the planet carrier, rotates at a lower speed and higher torque than the input shaft.

- Torque Amplification: Due to the multiple points of contact between the planet gears and the sun gear, planetary gearboxes can achieve torque amplification. The arrangement of gears allows for load sharing and distribution, leading to efficient torque transmission.

- Compact Size: The compact design of planetary gearboxes, achieved by stacking the gears concentrically, makes them suitable for applications where space is limited.

- Multiple Stages: Planetary gearboxes can be designed with multiple stages, where the output of one stage becomes the input of the next. This arrangement allows for high gear reduction ratios while maintaining a compact size.

- Controlled Motion: By controlling the arrangement of the gears and their rotation, planetary gearboxes can provide different motion outputs, including forward, reverse, and even variable speeds.

Overall, the design principles of planetary gearboxes allow them to provide efficient torque transmission, compact size, high gear reduction, and versatile motion control, making them well-suited for various applications in industries such as automotive, robotics, aerospace, and more.

editor by CX 2023-09-28

china price Customized Planetary Gearbox Used for Arm Hole Mining Chain Saws manufacturers

Product Description

Product Description

SGR planetary equipment motor

Complex information:

1. Ratio range: 8.1-191

2. Enter CZPT : .twelve-270 KW

three. Permit torque rang: ≤ 50000 N. M

4. Output speed: .3~205 r/min

5. Composition: Foot-mounted, flange-mounted, shaft-mounted

| Input structure | motor,IEC flange |

| Output speed | motor,IEC flange,enter shaft |

| reliable shaft, hollow shaft with crucial,with shrink disk |

Attribute:

one. Adopt optimized design and style, module mixture, right angle output, room reduction

2. CZPT strength and CZPT evity gears

three. Can be combined with CZPT motors, broader ratio selection

four. Large output torque, effortlessly startup, substantial effectiveness

Production images:

———————————————————————————————————————————————

FAQ:

1.Are you a manufacturing facility or trader ?

We are a professional factory which has 20 a long time historical past specialised in gear transmission .

2.MOQ:

Our MOQ is 1pcs. Even so there is a single handling value $a hundred and fifty for the single order which significantly less than $3000.00

three. Warranty

Our warranty is 12months

4. Payment phrase

100% T/T in CZPT and LC at sight .

5. Do you acknowledge CZPT ization ?

Yes.SGR have powerful R&D staff, we can give CZPT izable service according to specifications.

six. Packing

Generally we use standard export plywood situation to set up the cargo .

seven. Shipping time

In typical ,time of delivery is 30days following obtaining the prepayment .

eight. What kinds of certification do you use ?

DNV-ISO9001:2008, SGS,CE and many others, And new goods patent.

nine. What varieties of inspection you do before shipment ?

We do temperature check, noise, and oil leak inspection and commissioning ahead of shipment.

ten.How do you solve if the generation have problem ?

Largely, we do not want CZPT er send out the items back to us. Due to the fact the value is extremely substantial, if there fulfills a dilemma,we firstly ask for the pictures for destroyed components. And base on the pictures, we can have a standard notion for the defect cause. Our guarantee is twelve months, if during the promise, we can source repair .

in Milan Italy sales price shop near me near me shop factory supplier Agricultural Chain Ca650 Ca550 Ca557 Ca550V Ca555 Ca2060h manufacturer best Cost Custom Cheap wholesaler

EPG is a specialist maker and exporter that is concerned with the style, improvement and generation. a specialised provider of a total range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers. In 2000, EPG took the guide in attaining ISO14001 setting administration certification and thereafter handed the inspection of clean creation and recycling economic system, successful the title of “Zhejiang Inexperienced Enterprise”. We can offer the EPTT EPTT CA650 CA550 CA557 CA550V CA555 CA2060H in substantial good quality and competitive price

We also source Blend EPTTs or StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd Forged Combination EPTTs are utilized for EPTT, conveyor or elevating reasons. The interior hyperlinks of combination EPT are forged of malleable iron integrally even though the out hyperlinks are metal made. Equally riveted and cottered (spEPTT cotter or T cotter) constructions are offered.

Malleable solid iron EPTs H82 H130 H138 H78 H78A H78B C188 C188-K2 BRH188 C55 C55A C55B C55D, drop solid EPT EPT

We create all types of: 462 477 488 488K1 H82 H130 H138 H60 H78 H78A H78B C188 C188-K2 BRH188

Malleable cast iron EPTs H60 H78 H78A H78B C188 C188-K2 BRH188 C77 C102B C102B-K2 C131 C55 C55A C55B C55D,

Fall solid EPT EPT C77 C102B C102B-K2 C131C55 C55A C55B C55D

The merchandise are largely sold to the Center EPT, Europe and the The usa with a lot more than 20 a long time of heritage. We also hope to deveXiHu (West EPT) Dis.Hu (West EPT) Dis. a lot more new courses with enterprise business. For other items not detailed, you should ship e-mail for data:

HangEPT EPTT Market EPTT, Ltd. Is a EPTTized supplier of a entire range of EPTs, sprockets, EPTs, EPT racks, pulley, couplings, keyless locking device, bush, conveyor line spare parts, car accessory, EPTT, and other EPTT spare areas.

Contact US

in Sargodha Pakistan sales price shop near me near me shop factory supplier Hot Sale Sets Link Assy Standard Keyway Chain Wheel Sprocket manufacturer best Cost Custom Cheap wholesaler

Hangzhou EPG Co.,Ltd. , was launched in November, 1997. With its five wholly owned subsidiaries. We will give best providers and high quality items with all sincerity. We are looking forward to creating effective company interactions with new clientele close to the entire world in the long term.

Solution specification

1.EPT:C 45# steel ,stainless steel or other necessary supplies.

two.EPTs can be produced according the customer’s drawings

3.Warmth treatment: Hardening and Tempering, EPT Frequency Quenching, Carburizing Quenching and so on according the specifications..

4. Inspection: All items are checked and analyzed extensively for the duration of each working treatment and following generation will be reinspected.

About us

HangEPT EPT EPT EPTT, Ltd. is a specialist manufacturer of a variety of sprocket wheels, stainless steel sprocket wheels, non-stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd sprocket wheels, big pitch sprocket wheels, coupling sprocket wheels, spur EPTs, timing belt wheels, EPT racks, umbrella EPT, worm EPT, shaft, sleeve and other EPTT areas producers. And according to consumer drawings, samples, dimension processing custom made production. The firm integrates design and style R amp D, producing and revenue. In accordance with stringent creation, inspection and quality stXiHu (West EPT) Dis.Hu (West EPT) Dis.rds, EPT has estabEPTTd a complete top quality system, creation method and ideal quality control. The company’s sprocket goods are of high high quality, balance and toughness.

The organization now has 80 sets of a variety of substantial-precision CNC lathes, EPT hobbing EPTTs, EPT shapers, tempering furnaces, quenching gear, gantry planers, EPT milling, sawing EPTTs, vertical broaching EPTTs, EPT EPTTs and other processing products, with an once-a-year production capability of two million parts . Carburizing and quenching, nitriding, quenching and other warmth treatment, area blackening, galvanizing, electrophoresis, and so forth. At the very same time, it also has high-precision screening products this sort of as: Rockwell hardness tester, Vickers hardness tester, metallographic microscope, impression measuring instrument, EPTic particle flaw detectors, and so on. The items produced are extensively used in metallurgy, metal, chemical, textile, agricultural EPTTry, three-dimensional XiHu (West EPT) Dis.Hu (West EPT) Dis.ages, EPTT EPTTry, chemical EPTTry, pharmaceutical EPTTry, EPTT and mining EPTTry and other EPTT. The product indicators meet the needs of EPTTing similar merchandise and are exported to EPT and EPTTiwan, SouthEPT Asia, Europe, The usa, the Center EPT and other locations, and are deeply EPTTed and praised by consumers.

FAQ

Q: Are you trading organization or producer ?

A: We are factory.

Q: How EPTT is your shipping and delivery time?

A: EPTTly it is 5-ten daEPTTif the goods are in stock. or it is 15-twenty daEPTTif the items are not in inventory, it is in accordance to quantity.

Q: Do you give samples ? is it cost-free or extra ?

A: Indeed, we could provide the sample for cost-free demand but do not shell out the EPT of freight.

Q: What is your conditions of payment ?

A: Payment thirty%TT in EPT. 70% T/T before shippment.

Q:What`s the MOQ of your items?

A:1 set,we can also offer with the sample order. and the massive-amount.

in Bali Indonesia sales price shop near me near me shop factory supplier Hollow Pin Chain for Metric Conveyor Chain with British Standard manufacturer best Cost Custom Cheap wholesaler

a specialised provider of a total range of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers. In 2008, it was awarded with “Nationwide Export Commodity Inspection-free of charge Business”. It has established steady cooperation with a lot of properly recognized universities and institutes in china this kind of as, Zhejiang College, Jilin University, Specialized committee of national chain travel standard, Institute of nationwide chain generate, Zhejiang software engineering content institute, Huhan content security institute and it cooperated to identified China 1st Automobile chain institute with National chain drive institute.

MC Collection Hollow Pin Chains:

EPTT Metal and Stainless Metal Hollow Pin Chain for foodstuff handling conveyors. EPTT are accessible in EPTT stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd series, double pitch series with stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd rollers, and huge rollers.

This EPTT has hollow pins so that the holes can be employed to mount numerous pins and attachments.

| Product Title |

MC Series Hollow Pin Chains |

| Variety | MC28, MC56, MC112, MC224 |

| Color | major |

| EPTT | carbon steel, alloy steel,stainless metal |

| Customize | Indeed |

| OEM | Of course |

| Surface Therapy | rust-preventative oil |

| EPTT Sort | sea amp air |

| Market place | EPTT |

| Payment Terms | T/T EPTT |

| EPTT | carton,picket scenario,pallet |

Main goods:

EPTT Chains:

StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd Roller Chains/ Nickel-Plated Roller Chain/ Stainless Metal Roller Chain/ Bicycle Chain/ EPTTcycle Chain/ Chains for EPTTmotive Engines/ Leaf Chains/ Silent Chain.

Conveyor Chains:

Tiny Measurement Conveyor Chains/ Large Dimension Conveyor Chains/ Roller Conveyor Chain/ Hollow Pin Chain/ Travel Chain/ Metal Bushing Chain/ Welded Metal Mill Chain/ Welded Metal Drag Chain/ Barloop Chain/ Fall Forged Rivetless Chain/ Caterpiller Push Chain/ Cast Blend Chain/ Forged Pintle Chain/ EPTT Flex Chain/ EPTTty Chain/ Plastic Prime Chain/ Snap EPTT Chain.

Hyperlink Chains:

Quality one hundred twenty Alloy Chain/ Grade a hundred Alloy EPTT/ Quality eighty EPTT Chain/ Quality 70 Transport Chain/ Grade 50 Stainless Steel Chain/ Quality 43 Substantial Test Chain/ Quality 40 Higher Examination EPTT/ Grade thirty Evidence Coil Chain/ EPTT Loop Chain/ One Jack Chain/ Twist Chain/ Register Chain/ Ball Chain/ Oval Url/ Square Chain.

EPTTs:

Solitary Sort A Hub/ Solitary Variety B Hub/ Single Type C Hub/ Solitary Variety D Hub/ EPTT Strand Variety B Hub/ EPTT Strand Kind C Hub/ Hardened Enamel Kind A/ EPTT Solitary Sort A EPTT/ EPTT Pitch Strand Variety B Hub/ Large Roller EPTT Pitch EPTT.

Gear amp Rack:

Spur Gears/ Helical Gears/ EPTTl Gear/ Hypoid Gears/ Worm Gear/ Internal Helical Gear/ Herringbone Gears/ Rack And Pinion Gears/ Sector Equipment/ Internal Ring Gear/ Miter Gears/ Nylon Gear Rack.

Wire Mesh:

Woven Wire Mesh/ Plain Weave/ Twilled Weave/ Basic Dutch Weave/ Twilled Dutch Weave/ Reverse Plain Dutch Weave/ Reverse Twilled Dutch Weave/ 5 Heddle Weave/ Super Mesh Weave/ Welded Wire Mesh/ Wire Mesh Belt.

Shackles:

Screw Pin Anchor Shackle/ Spherical Pin Anchor Shackle/ Bolt Type Safety Anchor Shackle/ Screw Pin Chain Shackle/ Round Pin Chain Shackle/ Bolt Type Safety Chain Shackle.

Hooks:

Clevis EPTT Hook/ Clevis Seize Hook/ Eye EPTT Hooks/ Eye Seize Hook/ Clevis Foundry Hooks.

EPTTs:

Chain EPTTs/ Wire Rope Clip/ Link/ Coupling Link/ Quick Link/ Snap Hooks/ Eye Bolt/ Turnbuckle/ Anchor Rod/ Swivels/ Cable Thimble.

EPTTry EPTT:

Belt conveyors/ Scraper Conveyor/ Chain Conveyor/ Plate Conveyor/ Roller Conveyor/ Spiral Conveyor/ EPTT Conveyors/ Incline Conveyor/ Vegetable And Fruit Processing EPTTs/ Foods Processing EPTTry/ Dairy Processing EPTT/ Slaughtering EPTT/ Brewing EPTT/ Frozen Drink EPTT.

Firm info:

We are engaged in the EPTT and export of EPTT EPTT.

We have expert manufacturing unit. EPTT is robust in products of different specifications total, has robust product deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment and manufacturing capability.to supply all kinds of EPTT tools products, specs total, selection, good quality, reasonable price.

Our Benefits:

Our company has above twenty years’ encounter creating substantial-top quality EPTT goods.

The goods are trustworthy and we can manufacture the products according to customers’ requirement.

We can also cooperate with customers to deveXiHu (West Lake) Dis.Hu (West Lake) Dis. new merchandise.

Our goods have been licensed by CE and ROHS, also can give EPT solution Certificate.

We sincerely welcome domestic and overseas, new and aged customers to carry on the cooperation and trade with us, and build a EPTT-time cooperative connection.

Business Identify: EPTTngdao EPTT EPTT Hao International EPTT Co., Ltd.

China manufacturer & factory supplier for 08b in Nnewi Nigeria stainless b series china roller chain with ISO certified With high quality best price & service

Manufacturer of roller travel chains for electricity transmission apps from general industrial to functions in specialized locations these kinds of aThe lubrication of this equipment reducer kind is continual and arrives as regular, with large quality refined oil which has antirust and antiwear products with Fe, Cu and alloy protectors that has CLP DIN 51517-3, FGZ degree 12, AP GL-4, US 224, AGMA 250-04 amount of good quality for that explanation its servicing is not essential.s meals processing, hefty building gear, and oil area providers. Available in double pitch drive and regular roller chains with one and numerous strand configurations. Requirements contain .twenty five to 3 in. chain pitch, .13 to 1.88 in. distance in between sidebars, and .09 to .ninety four in. pin diameter. Offered with functions this kind of as circumstance-hardened and armor-cased pins, pre-stressed method, corrosion and shock resistance, and stainless steel resources. Provides publish-sale assist solutions.We offer OEM support.

Overview

Swift Details

- Relevant Industries:

-

Producing Plant, Machinery Repair Retailers, Retail

- Normal or Nonstandard:

-

Nonstandard

- Kind:

-

Roller Chain

- Content:

-

ALLOY

- Tensile Energy:

-

17.eighty to forty four.50KN

- Location of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

- Item identify:

-

08b stainless b collection china roller chain with ISO qualified

- Versions:

-

The organization masking 88,000 square meters, has superior products and powerful technological toughness, these kinds of as the numerical control machine resources and machining centers, CAD/CAM program, industrial robotic and many others.

08B

- Pitch:

-

twelve.70mm

- Roller Diameter:

-

eight.51mm

- Interior Width:

-

seven.75mm

- Pin Diameter:

-

4.45mm

- Sidebar Height:

-

eleven.81mm

- OEM:

-

Offered

- Trial Get:

-

Offered

- Packaging:

-

can be custom-made

Source Capacity

- Source Ability:

- one hundred thousand Meter/Meters for every Thirty day period 08b stainless b series china roller chain with ISO certified

Packaging & Delivery

- Packaging Particulars

-

or as Customer’s demand for 08b stainless b collection china roller chain with ISO qualified”>Pallet, Veneer Scenario, Wooden Scenario

or as Customer’s need for 08b stainless b sequence china roller chain with ISO licensed

- Port

- Shanghai

-

Guide Time

: -

Amount(Meters) 1 – three hundred 301 – one thousand >1000 Est. Time(times) 45 65 To be negotiated

Slip clutch sort on the rotary tiller, once again slight oozing of grease on the UJ, do not grease the clutch these operate dry and need to be “slipped” at the very least when a year to prevent rusting jointly

On the web Customization

08b stainless b collection china roller chain with ISO qualified

Item Description

We, EP CHAINS, focus in planning and manufacturing industrial chains, with above 30 years background in this sector. Our factory occupies sixty,000 square meters, with investments in machineries our mounted belongings achieving to eighty million RMB. We have a extremely energetic administration crew, skilled and expert staff. The complete workers increase to one hundred eighty in 2018.

With our specialty in making chains for conveyor, transmission and dragging, our goods have been exported to United states of america, Canada, Europe, Japan, South The united states, Southeast Asia, Africa, the Middle East and other countries and we have proven sound connections with some important players in the connected industries. In 2018, the total turnover reaches 14 million USD.

Our items have passed ISO:9001 top quality management program and stand the end users’ ordeal. We devote ourselves to manufacture the large-high quality goods with aggressive prices, we know the industries well, therefore from layout to material variety, till production technique is up to the substantial standard, in the meantime our preparing staff and worldwide staff will guarantee the punctual shipping.

We have stringent quality manage, each buy has person report and will be kept in file.

We welcome the OEM inquires and just remember we are skilled in supplying the solution for the chains in the industries of Sugar, Palm oil, Wood, Cement, Automobile, Paper, Asphalt , Food, ,Drinking water therapy, Mining, Automation…

Also, welcome to visit our manufacturing facility and you will find satisfaction…

EP Chains hereby certify that if you discovered any defect in our material or method of any variety of item,which will be free of chargeif you found any product was inconsistent with the acceptance drawing or sample soon after the delivery,we can settle for the return or rework of products and find the money for any demand about this.

|

Product name |

08b stainless b sequence china roller chain with ISO qualified |

|

OEM |

Offered |

|

Samples |

Obtainable |

|

Demo Order |

Available |

|

Packing |

Can be tailored |

|

Shade |

Character |

|

Certification |

ISO9001:2015 |

|

Perform |

Transmission |

|

Payment |

T/T,L/C,D/A,D/P, Western Union |

|

Therapy |

Warmth Remedy |

|

Content |

Alloy Metal |

|

Normal |

DIN GB ISO JIS BA ANSI |

|

Brand name |

EP or OEM |

Services:

· we will send you all inquiries in 1 working day.

· As new solution,the mould can be free if the sum much more than USD20,000.

· As our Sincere buyers,we can make the chains with no minium amount.

· The delivery time is 6 weeks.

· The samples can be sent for free as aid you to open up the industry.

FAQ

Why chose us??

1. We are engaged in chain market above 30 several years with wealthy industry encounter. We keep enhancing manufacturing methods. All the products have longer functioning daily life and have handed the marketplace test.

two. According to abrasion resistance, corrosion, reinforce doing work life, we can layout the chains for you on each and every industry.

We can design the appropriate chains with substantial good quality materials, excellent abrasion resistance, great corrosion, higher improve and etc as for each your request or the chain application

3. We are the chain producer you can immediately obtain the merchandise from us with minimal value and substantial top quality.

We are the chain company, you can get the goods with lower price and higher top quality

4. We have a skilled team for global trade, they have considerable activities and are often ready to remedy difficulties for customers. So you have absolutely nothing to be concerned about.

five. We have the prolonged-expression cooperative forwarder who can give us the least expensive freight. And it can assist you to help save the freight. What is much more, for the FCL, we will design and style the deals as per the container sizes with the biggest capacity to help save the shipping and delivery expense for both of us.

Programs

Packaging & Delivery

Contact

If you want to know a lot more,you can go to our site:http://epchain.en.alibaba.com

Extended near me shop made in China – replacement parts – in Sacramento United States Pin Drop Forged Chain X458 with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 diverse branches. For a lot more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Prolonged Pin Fall Solid Chain X458

Our Drop forge rivetless Chain are widely utilised in conveyor linesDrop cast rivetless chain,Fall forged chain,cast chain, forged conveyor chains ,forged suspending chain,fall forged rivetless chain and yokes, forged suspending chain, Scraper chain,square chain, steel detachable chain, painting line chain, Cat Pilar chain. Caterpillar chain, drop cast website link, drop cast conveyor chain, conveyor chain, automobile assembling line chain, forged scraper chain, fall cast folding chain, detachable chain this kind of as X348 chain, X458 chain, X678 chain, X698 chain(698 chain), P142 chain(scraper chain), P142V chain, P142H chain, P200 chain, P102 chain, P260 chain, P250 chain, detachable chain 51 chain, 52 chain, 55 chain, 57 chain, sixty two chain, seventy four chain, 78 chain

Offered items:

1) X348, X458, 468H, X678, 698, 698H, F100x16, F100x17, F160x24 drop forged rivetless chain

2)Removable chain, this sort of as fifty five,57,sixty two,seventy four,seventy eight etc

3)Cast website link : this kind of as one hundred and one.6*36*8 , 142*50*19,142*fifty*29,200*fifty*twenty five etc

4)Cat Pilar chain /Caterpillar chain of 348,458,678 and many others .

five)Attachment of 348,458,678 and so forth

6) Cost-free Trolley

We are major provider of Drop Forged Rivetless Chain, drop forged chains, fall solid url, fall cast conveyor chain, conveyor chain, vehicle assembling line chain, cast scraper chain, drop forged folding chain, removable chain these kinds of as X348 chain, X458 chain, X678 chain, X698 chain(698 chain), P142 chain(scraper chain), P142V chain, P142H chain, P200 chain, P102 chain, P260 chain, P250 chain, detachable chain 51 chain, 52 chain, 55 chain, fifty seven chain, 62 chain, 74 chain, seventy eight chain and so on. We can create as for every your drawing or sample also. Our goods are mo EPT competitive and are of large good quality. Our trolley are also mo EPT aggressive in world industry.

For scraper chain, we can weld the scraper for you or as for each your reque EPT set up bolt for your nylon scraper and so on. We will produce as for each your drawing or sample. Content can be 40Cr, 20CrMnTi, 42CrMo and so on as for each your request.

For drop cast suspending chain, there are prolonged pin chain, pusher and so on to meet up with distinct customer’s request.

We also generate special chain and pin and plate as for each customer’s sample or drawing.

We are also supplier of detachable chain. Please truly feel totally free to get in touch with with us and our goods are mo EPT aggressive in your marketplace.

If you have any require of our merchandise , please really feel free of charge to let me know your element enquiry and we will offer you our be EPT value and service for you ASAP.

Over ninety% of our item are exported to United states of america, CANADA, JAPAN, KOREA, BRAZIL, AUSTRALIA and so on. Remember to truly feel cost-free to speak to with us for your venture

Company Info

HangZhou EPT Market Co., Ltd. is a specialized supplier of a total variety of chains, sprockets, gears, equipment racks, v belt pulley, timing pulley, V-belts, couplings, machined parts and so on.

Owing to our sincerity in giving be EPT support to our clientele, comprehending of your demands and overriding sense of responsibility toward filling buying demands, we have obtained the tru EPT of purchasers globally. Possessing amassed treasured encounter in cooperating with international customers, our products are marketing nicely in the American, European, South American and Asian markets.Our goods are created by modern day computerized machinery and equipment. Meanwhile, our products are produced in accordance to high top quality specifications, and complying with the intercontinental sophisticated regular standards.

With several years’ knowledge in this line, we will be trusted by our rewards in aggressive price, one-time delivery, prompt reaction, on-hand engineering help and very good soon after-income services.

In addition, all our production techniques are in compliance with ISO9001 expectations. We also can layout and make non-common items to satisfy customers’ special requirements. Quality and credit rating are the bases that make a corporation alive. We will supply be EPT services and large high quality goods with all sincerity. If you need any details or samples, you should make contact with us and you will have our shortly reply.

Packaging & Transport

Exhibition

Make contact with us

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For much more information: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original tools manufacturer’s (OEM) portion numbers or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our firm and the shown substitution areas contained herein are not sponsored, accredited, or created by the OEM.